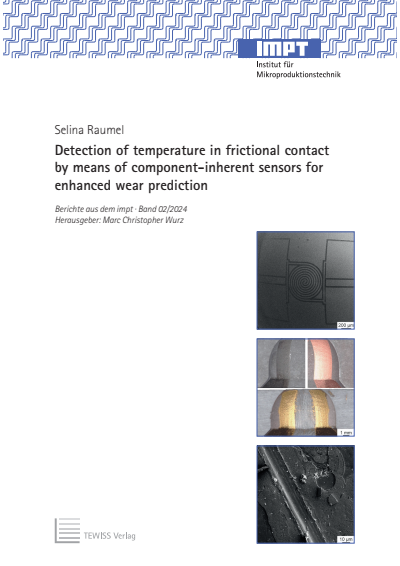

Detection of temperature in frictional contact by means of component-inherent sensors for enhanced wear prediction

- Autor:innen:

- Reihe:

- Berichte aus dem IMPT, Band 02/2024

- Verlag:

- 2024

Zusammenfassung

Within the scope of this work conducted in the Collaborative Research Center 1368 »Oxygen-free production”, a new component-inherent sensor concept on non-planar surfaces is presented for measuring friction-induced temperature changes as a function of atmosphere, process parameters and ambient temperature during frictional ball-on-disc tests to improve wear prediction. The development and manufacturing of the platinum thin-film sensors on ceramic spheres via laser ablation involves the characterization of suitable sensor layouts, wear-resistant/isolation and friction layers. A laser structuring process is developed for machinable BN+AlN components to enable mechanical contacting of the sensors via the ball mount outside the friction contact area. Using an expanded measurement setup, friction tests are conducted under ambient atmosphere and under an atmosphere adequate to an extremely high vacuum using a silane-doped argon gas. To assess the fundamental effects of the friction-induced temperatures and their impact on resulting boundary layers, surface-sensitive analysis techniques are employed. Indentation tests are conducted in a high-temperature chamber to examine the thermomechanical properties in dependence of the surrounding atmosphere. The insights gained are utilized to expand the well known Archard wear model by including the dependence of the measured friction-induced temperature and atmosphere.

Schlagworte

Publikation durchsuchen

Bibliographische Angaben

- Auflage

- 1/2024

- Copyrightjahr

- 2024

- ISBN-Print

- 978-3-95900-946-1

- ISBN-Online

- 978-3-95900-946-1

- Verlag

- TEWISS, Garbsen

- Reihe

- Berichte aus dem IMPT

- Band

- 02/2024

- Sprache

- Deutsch

- Seiten

- 173

- Produkttyp

- Monographie

Inhaltsverzeichnis

- Titelei/Inhaltsverzeichnis Kein Zugriff Seiten I - XX

- 1. Introduccion Kein Zugriff Seiten 1 - 3

- 2.1 Introduction of friction and frictional contacts Kein Zugriff

- 2.2 Wear mechanisms Kein Zugriff

- 2.3 Influences on friction and wear Kein Zugriff

- 2.4 Mathematical modelling of wear Kein Zugriff

- 3.1 Tribometer Kein Zugriff

- 3.2 Overview of analytical wear models Kein Zugriff

- 3.3 Mathematical contact and flash temperature models Kein Zugriff

- 3.5 Temperature measurement methods in frictional contacts Kein Zugriff

- 3.6 Laser technology for sensor production Kein Zugriff

- 3.7 Laser direct structuring on ceramics Kein Zugriff

- 4.1 Initial situation Kein Zugriff

- 4.2 Research questions Kein Zugriff

- 4.3 Task and objective Kein Zugriff

- 4.4 Approach Kein Zugriff

- 5.1 XHV-adequate atmosphere Kein Zugriff

- 5.2 Universal Mechanical Tester (UMT) Kein Zugriff

- 5.3 Cathode sputtering system Kein Zugriff

- 5.4 Analysis and characterization Kein Zugriff

- 5.5 Thermal stress analysis Kein Zugriff

- 5.6 Sensor production and contacting Kein Zugriff

- 5.7 Electrical measurements and characterization Kein Zugriff

- 5.8 Analytical modelling and simulation Kein Zugriff

- 5.9 Adhesive strength analysis Kein Zugriff

- 5.10 Sensor parameters Kein Zugriff

- 5.11 Properties of technical ceramics Kein Zugriff

- 6.1 Experimental boundary conditions Kein Zugriff

- 6.2 Material selection and sensor design Kein Zugriff

- 6.3 Selective laser ablation of the sensor structure Kein Zugriff

- 6.4 Characterization of the component inherent sensors Kein Zugriff

- 6.5 Interim summary of the sensor development Kein Zugriff

- 7.1 Process development of laser direct structuring on ceramic materials Kein Zugriff

- 7.2 Contacting Kein Zugriff

- 7.3 Transfer of the developed process to a machinable ceramic material Kein Zugriff

- 7.4 Characterization of the conductive tracks Kein Zugriff

- 7.5 Interim summary - LDS on ceramic substrates Kein Zugriff

- 7.6 Production and metallization of the ceramic sphere holder Kein Zugriff

- 8.1 Integration Kein Zugriff

- 8.2 Experimental set-up Kein Zugriff

- 8.3 Results and discussion of the measurements Kein Zugriff

- 8.4 Comparison to mathematical results Kein Zugriff

- 8.5 Summary and discussion of the results Kein Zugriff

- 9.1 Real contact area Kein Zugriff

- 9.2 Friction induced temperature Kein Zugriff

- 9.3 Mechanical and tribological properties Kein Zugriff

- 9.4 Wear calculation Kein Zugriff

- 9.5 Experimental validation of the model Kein Zugriff

- 10 Concluding, Remarks and Perspektives Kein Zugriff Seiten 127 - 130

- A.1 Appendix I : Overview of the scope of work for the sensor production Kein Zugriff

- A.2 Appendix II - XHV-adequate atmosphere Kein Zugriff

- A.3 Appendix III - Results temperature measurements Kein Zugriff

- A.4 Appendix IV - Additional measurement attempts Kein Zugriff

- A.5 Preliminary simulations Kein Zugriff

- A.6 Appendix V - xSol Kein Zugriff

- A.7 Appendix VI - Samples after the friction tests Kein Zugriff

- A.8 Appendix VII - Overview of the mathematical model Kein Zugriff

- A.9 Appendix VIII - First preliminary tests on glass Kein Zugriff

- Bibliography Kein Zugriff Seiten 143 - 173